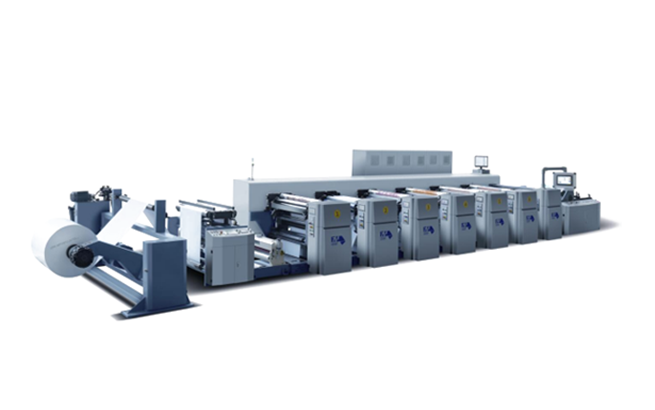

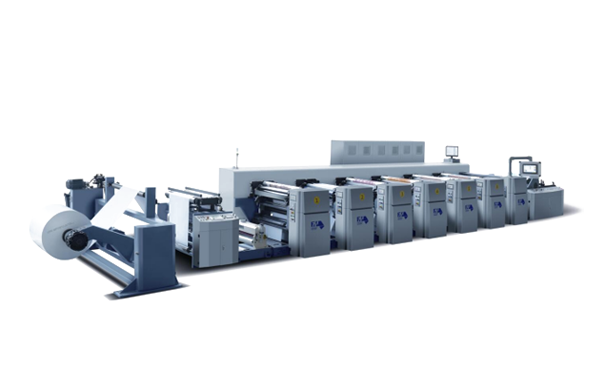

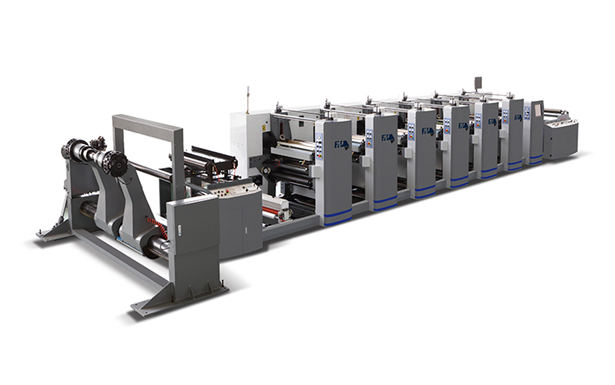

Function Units

1.Unwinding Unit

- Shaftless unwinding unit

- Unwind unit 60”(1524mm)capacity

- Mandrel 3” and 6” diameter

- Hydraulic paper shaft lifting and descending device: mainly used for loading and unloading of paper rollers, no need of forklift or other handling tools

- Web break sensor, automatically shut down when paper broken

2. Web Guide System

- Paper Splicing Table : with pneumatic paper holding device.

- Ball screw electric actuator

- Adopt the photoelectric sensor for web guide transmission

- Electronic web guide traction device. If there is any excursion in paper feeding,the system will have a constant and accurate adjustment

- Adopt closed loop control system to accurately detect the deviation and correct it

- Hard Anodization to the paper guide HV 800-1000

- Inspection:the edge

- Web Guide precision:±0.02mm

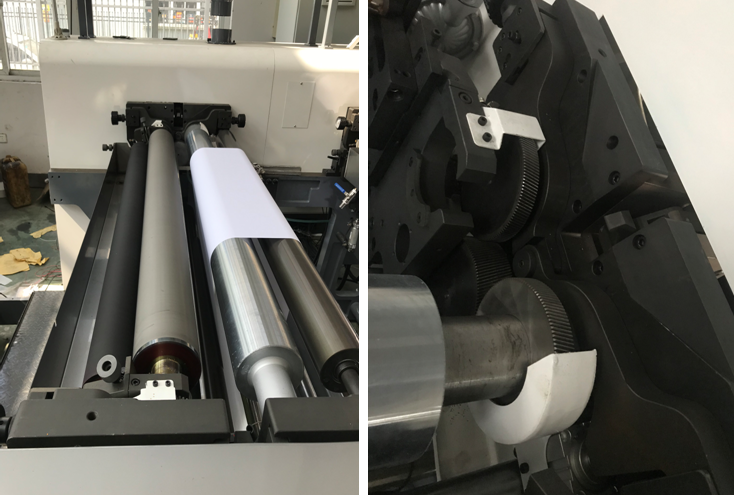

3.In-feed Tension Control Unit

- Use the double side pressure rubber roller to clutch and feed paper and to ensure the tension

- Infeed unit with servo motor drive, epicyclic gear box

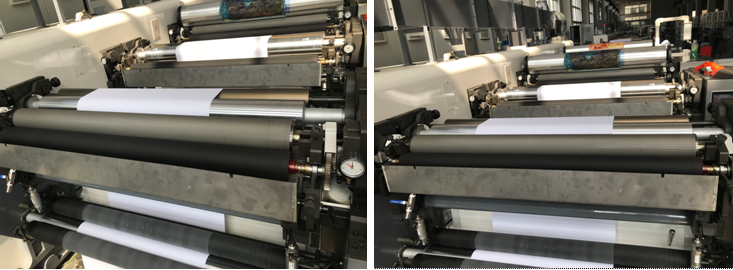

4.Printing Units(shaftless, single servo motor drive in each station)

- Servo motor conrtol press cylinder,can realized the pre register function, the anilox roll and printing cylinder are gear box drive

- Plate cylinders is designed in flower type structure and the plates can be changed without tools and no need adjust the pressure.

- The machine double sides frame is made of overall alloy and cast iron, which improves the stable performance and durability of the press machine

- High precision ceramic anilox roll with micro-metric adjustment

- Automaticc vertical registration.

- Reversed single doctor blade

- self-cleaning plate feature.The anilox and plate cylinders release alternately, transfering residual ink to the paper when machine stop, leaving the printing plates clean and minimizing the need of hand to clean the plates

- When press stops, the anilox roll continuous running. Hence avoiding permanent damage, which is caused by ink drying on the anilox surface

Auto Register:

- The first color printing unit is the benchmark and the following printing unit registers automatically according to the first color.

- The automatic registration controller can adjust the phrase position of the servo motor according to the detected error, realizing the quick registration, improving the operating quality and the extent of automation, so the machine greatly reduces the labor intensity and attrition rate of raw materials

5. Drying Units

- Every printing unit has one seperate drying unit

- High efficiency drying unit including infra red lamps, air blowing/suction system. Air intake adjustable, Air circulation design on the exhaust, the blower is adjustable

- Short wave infrared heating elements

- Natural air blowing assembly with exhaust fan

6. Video Web Inspection System

- Video is high efficency and synchronous, can be moved left and right

- With 14 inch monitor one pcs

- one stroboscope lamp

- It can be enlgared 18 times of image

7.Out Feed Tension Control System

- The rear tension unit is made of alloy and cast iron

- Use the double side pressure rubber to cluth and feed and to guarantee the stale tension

- unit with servo motor drive, epicyclic gear box

8.Rewinding Unit

- rewind unit 60’’(1524mm)capacity, with 3’’ shaft,

- Hydraulic roll lift

- Web break sensor, automatically shut down when paper broken.

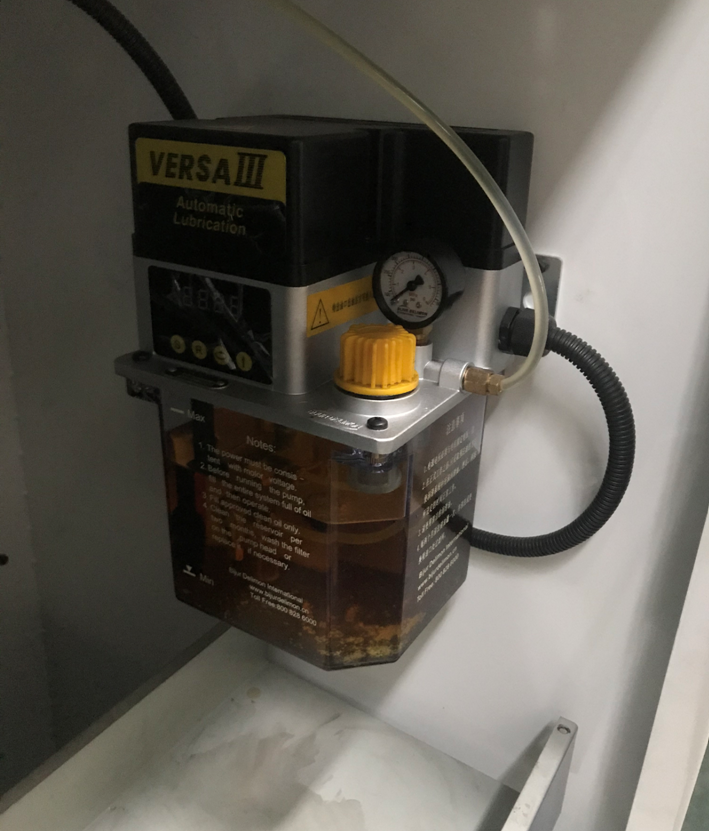

9. Automatic Lubricating System

- The gear’s automatic dampening system can adjust the lubricating time and ration

- When the dampening system breaks down or the lubrication is not enough, the indicator will alarm automatically.

10. Plate Mounter

- It has a screen including the bilateral symmetrical split screen display

- It is used for the plate mounting to realize the purpose of multi-color overprinting

- One set image segmentation device

- 2 high definition cameras for magnifying

- Quickly changes the print plates

11.Web cleaner and anti static unit

- To guarantee the cleanness of substrates

- First remove static, then clean the dust in vacuum and then remove static

12.Corona Treater (Optional)

- To increase ink adhesion to film side of printing materials

|

Specification |

CS1020 |

CS1120 |

CS1220 |

CS1320 |

CS1350 |

CS1450 |

|

Max. Web Width |

1020mm |

1120mm |

1220mm |

1320mm |

1370mm |

1450mm |

|

Max. Printing Width |

1000mm |

1100mm |

1200mm |

1270mm |

1350mm |

1430mm |

|

Printing Repeat |

320-1200mm |

320-1200mm |

320-1200mm |

320-1200mm |

400-1200mm |

400-1200mm |

|

Max. Unwinder Diameter |

1524mm |

1524mm |

1524mm |

1524mm |

1524mm |

1524mm |

|

Max. Rewinder Diameter |

1524mm |

1524mm |

1524mm |

1524mm |

1524mm |

1524mm |

|

Gearing |

1/8cp |

1/8cp |

1/8cp |

1/8cp |

1/8cp |

1/8cp |

|

Machine Speed |

240m/min |

240m/min |

240m/min |

240m/min |

240m/min |

240m/min |

|

Diameter of web roller |

100mm |

100mm |

100mm |

100mm |

100mm |

100mm |

|

Drying Mode |

Hot Air drying + IR drying, UV drying as optional |

|||||

|

Ink Used |

Water based Ink or UV Ink as optional ( need UV dryer ) |

|||||

|

Name |

Producer |

|

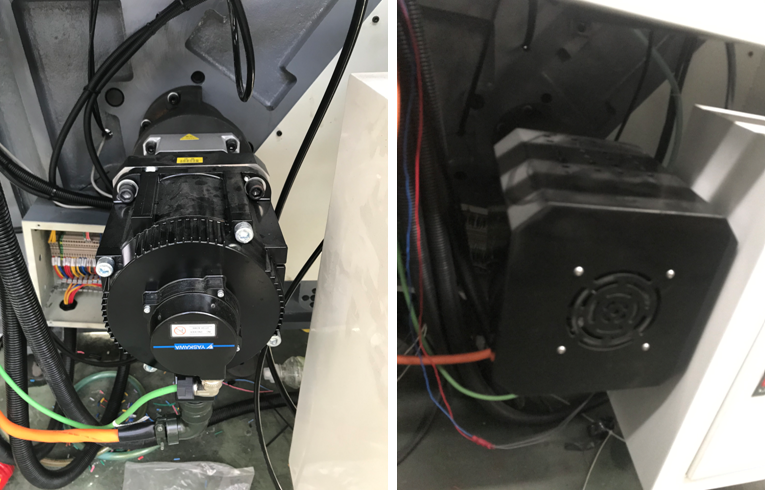

Servo Motor |

Japan YASKAWA |

|

Rewinding tension inverter |

Inovance |

|

Tension Controller |

KORTIS |

|

EPC web guiding |

Italy Selectra |

|

PLC |

Japan YASKAWA |

|

Text display |

FLEXEM |

|

Intermediate relay |

France Schneider |

|

Beaker |

France Schneider |

|

Contactor |

France Schneider |

|

Terminal block |

Germany Weidmuller |

|

Control button |

France Schneider |

|

Aviation plug |

Sibas |

|

Photoelectric sensor |

Germany Sick |

|

Proximity sensor |

Germany Turck |

|

Electrostatic dust collector |

The British Mickey Technology |

|

Automatic lubrication installation |

BIJUR DELIMON (Sino US joint venture) |

|

High-speed synchronous capture detection system |

ARISE |

|

Anilox roller |

Shanghai Yuncheng |

|

Anilox roller one-way bearing |

Japan Spring |

|

Deep groove ball bearing |

Japan NSK / Nachi |

|

Pneumatic components |

Taiwan Airtac |

|

Corona treater |

Nantong Sanxin brand |

|

Auto color-register system |

Kesai |

|

No. |

Product name |

Specifications |

Unit |

Quantity |

|

1 |

Infrared lamp |

Long & Short |

PCS |

Each 3 |

|

2 |

Three position self compound switch |

ZB2BD5C (Schneider) |

PCS |

2 |

|

3 |

Green Button |

ZB2BA3C (Schneider) |

PCS |

2 |

|

4 |

Black Button |

ZB2BA2C (Schneider) |

PCS |

2 |

|

5 |

Button Base |

ZB2BZ103C (Schneider) |

PCS |

2 |

|

6 |

Button Base |

ZB2BZ101C (Schneider) |

PCS |

4 |

|

7 |

T-junction |

PUT8-8-8 |

PCS |

Each 3 |

|

PUT10-10-10 |

||||

|

8 |

Pressure Regulating Valve |

AR2000JN (with 2pcs connection PC6-2) |

PCS |

1 |

|

9 |

Solenoid Valve |

4V21008B (with 4pcs PC8-2 & 8-1) |

PCS |

2 |

|

10 |

Pressure Gage |

F-GF-5004M |

PCS |

1 |

|

11 |

Air Pipe |

8mm |

Meters |

10 |

|

12

|

One Way Bearing |

BB30-2K-K |

PCS |

1 |

|

13 |

White Cloth |

|

PCS |

1 |

|

14 |

Blower Pipe |

125mm |

PCS |

3 |

|

15 |

Pipe Fastener |

110-135mm |

PCS |

64 |

|

16 |

Blower Pipe |

100mm |

PCS |

1 |

|

17 |

Pipe Fastener |

90-110mm |

PCS |

2 |

|

18 |

Pipe Fastener |

200mm |

PCS |

2 |

Tool Box List

|

Item No. |

Name |

Unit |

Quantity |

|

1 |

Allen wrench |

SET |

1 |

|

2 |

Pincer pliers |

PC |

1 |

|

3 |

Nipper pliers |

PC |

1 |

|

4 |

Spanner |

PC |

1 |

|

5 |

Hammer |

PC |

1 |

|

6 |

Oil can |

PC |

1 |

|

7 |

Tapeline |

PC |

1 |

|

8 |

Cross screwdriver |

PC |

1 |

|

9 |

Straight screwdriver |

PC |

1 |

|

10 |

#27 Spanner |

PC |

1 |

|

11 |

#17-19 Spanner |

PC |

1 |

|

12 |

#12-14 Spanner |

PC |

1 |

|

13 |

#8-10 Spanner |

PC |

1 |

|

14 |

#13 Spanner |

PC |

1 |

русский

русский français

français ES

ES العربية

العربية Português

Português 한국어

한국어