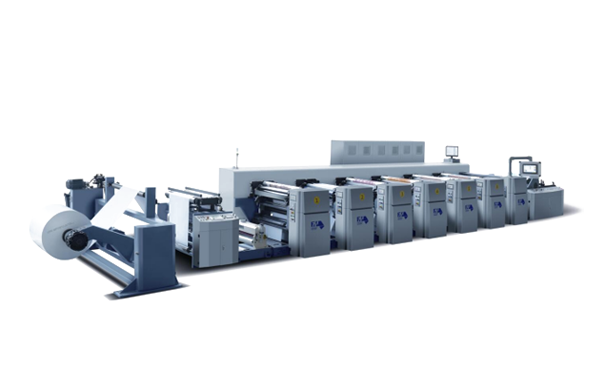

ⅠMain Technical Parameters

|

Max.web width |

1480mm |

|

Max.printing width |

1450mm |

|

Material core diameter |

Φ76mm( 3″);Φ152mm( 6″) |

|

Max.diameter of unwinder |

Φ1524mm(winding leveling) |

|

Material weight |

100—300 gsm |

|

Material tensile strength |

1kn/m—6kn/m |

|

Rewinder diameter |

Φ76mm( 3″) |

|

Max.running speed |

200m/min |

|

Registering precision |

±0.15mm |

|

Drying temperature |

40—120 ± 1℃infinitely variable control |

|

Tension precision |

300—1000N±5N infinitely variable control |

|

Ink supply |

Pneumatic diaphragm ink pump circulation system |

|

Registering mode |

Automatic color register with YASKAWA Brand |

|

Cleaning mode |

Online cleaning, centralized recovery of waste water |

|

Air supply |

8 Kg/m2 |

|

Power supply |

380V ± 10% 50Hz 3 phase |

|

Whole machine installed power |

620KW (7 color, 1450mm) |

|

Diemension |

32000×5000×3000mm(L×W×H) (just for reference, accurate data subject to actual installation) |

ⅡMain Characteristics

1.Flower type plate mounting, anilox and cylinder with quick change structure.

2.Printing unit easy opertion, cylinder and anilox pressing once successfully, adjusting-free design.

3.Plate full servo shaftless transmission, automatically pre-print, time saving & material saving.

4.Registering remains the same during lifting process.

5.High speed chamber doctor blade system without jilt ink.

6.50-180m/min nonstop paper unwinder

7. 200m/min nonstop paper rewinder.

8. High efficiency negative pressure dust removal unit;

9.More than 3m’s strong drying oven;

10.Three dof lifting device: cylinder, anilox roller, doctor blade can be quickly changed;

11. Adopt KESAI High-speed synchronous capture detection system。

Ⅲ Main Structure

1.Unwinder part

|

Nonstop unwinder |

Head butt joint paper unwidng, double-sided paste adhesive tape Paper unwinding speed:≤200m/min; Alarm function for paper runs out; |

|

|

Double station hydraulic shaftless auto loader |

Φ76mm( 3″)、Φ152mm( 6″) |

5 pcs |

|

Air brake |

Air-powered actuators |

4 sets |

|

Unwinding tension system |

France KORTIS |

2 sets |

|

Unwinding tension mode |

Pneumatic brake closed-loop constant tension |

2 sets |

|

Traction power Japan Shimpo |

High precision gear reduction motor |

1 set |

|

Paper feeding traction |

AC vector frequency conversion motor |

1 set |

|

Traction roller |

φ240mm Nitrile butadiene rubber, salt, 65-70 degrees Fahrenheit |

2 sets |

|

Main bearings |

Japan NACHI |

|

|

Inking motor |

Taiwan Chengbang(CPG) |

|

2 ITALY SELECTRA

|

Italy Selectra |

Taiwan Pausource |

1 set |

|

Web guiding |

With ultrasonic |

1 set |

3 Dust Extraction Unit & Pre-heating Unit

|

Single side dust extraction |

Switzerland double brush roller negative pressure dust removal |

1 set |

|

Paper Pre heating Unit with hot air |

60—80℃ |

1 s |

4 Paper in tension part

|

Process secondary tension |

100NM Magnetic powder brake Digital tension adjustment |

1 set |

|

Double roller paper in traction |

|

1 set |

5 Printing part(7 units)

- Petal type cylinder design, anilox and cylinder roller are quick changing structure;

- Printing plate full servo shaftless drive, automatic pre-register, saving time and material;

- In the process of acceleration and deceleration, the register conditions remain unchanged;

- High precision cam-type pressing and positioning mode; printing part "fool" type operation;

- Cylinder roller, anilox roller pressing position once in place, free adjustment;

- High speed and without jilt ink new closed doctor blade system;

- Register position automatic memory function

- Cylinder roller and anilox roller, printing roller clutch, automatic cleaning when stop;

- Free lifting device in the machine, make the plate roller, anilox, blade etc. replace conveniently

|

High strength cast iron wall, large pentahedron processing |

80mm |

7 pcs |

|

Ceramic anilox |

360—800 LPI |

7 pcs |

|

Plate roller |

Plate length range 520—1650mm |

7 pcs |

|

Chamber doctor blade |

Fengming patent |

7 pcs |

|

Printing unit |

AC servo motor YASKAWA |

7 sets |

|

Servo automatic register system |

YASKAWA |

5 sets |

|

Pneumatic components |

AirTAC |

7 sets |

|

Ink tank |

SS304 ,2.5mm |

7 sets |

|

Guide roller |

Aluminum alloy guide roll |

98 pcs |

|

Lifting device |

Imported low headroom lifting device in the machine |

7 sets |

6 Oven

- The total length more than 3m strong drying oven with independent temperature control,

- The front oven is heated by radiation, and the back oven is heated by strong hot air,

- The switching of oven is pneumatic control,

- Oven switching part uses the "9" note of rubber sealing structure, closed completely,

|

Strong drying oven |

|

10 sets |

|

Heater |

Finned heater |

12*5=60 pcs |

|

Circulating fan |

Shanghai |

5 sets |

|

Exhaust fan |

Shanghai |

1 set |

7 Computer stroboscopic system

|

400 LPI resolution still picture With electric scanning function |

China Kesai |

1 set |

8 Paper out tension part

|

Double roller paper out traction |

|

1 set |

9 Rewinding part

|

Surface coiling back type non-stop rewinder mechanism |

|

1 set |

|

Pneumatic safety auxiliary upper roller device |

|

1 set |

|

Hydraulic and pneumatic combined type roll changing mechanism |

|

1 set |

|

Rewinder shaft |

(3 inch) |

2 pcs |

|

Hydraulic unloading device |

|

1 set |

10 Control System

- Remote communication system, through the 3G/4G wireless network, remote diagnosis, remote maintenance; at the same time can be achieved by the user authorization management personnel on the operation of the equipment and the production of remote monitoring.

- 2. PLC controls following functions: printing unit auto-press in order,auto off-press when machine turn off; auto ink running; blower auto delay time and machine auto-stop etc.

- PLC controls following alarm: paper broken, paper used out, over-temperature.

- Machine is with following display parts: voltage,current, tension, EPC indication, alarm light, indication light

- High speed synchronous Capture detection system is Germay BST

- Each printing unit has separate control case with S.S plate is long life time

- B&R AC servo color register system is stable with high speed

- Machine’s working is with touch screen, easy to operate.

|

PLC |

YASKAWA |

1 set |

|

Touch Screen |

10″ |

1 set |

|

Ac servo synchronization control system |

YASKAWA |

1 set |

|

Low-voltage apparatus |

Schneider |

|

Ⅴ Wearing Part

|

The quartz heating light |

9pcs |

|

Button |

4pcs |

|

Relay |

4pcs |

|

Sealing Part for Blade |

7sets |

|

Joint for Air pipe |

8pcs |

|

Air Shaft Accessory |

2 pcs |

Ⅵ Workshop production condition(User configuration)

The best condition:

- Temperature 25±3℃

- Relative humidity 50%--70%

- Net Height >3.5M

- u Clean, dust-proof, anti mosquito.

русский

русский français

français ES

ES العربية

العربية Português

Português 한국어

한국어